Model: SRP SERIES

Automatic Spring Roll And Samosa Pastry Sheet Machine

SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is a food processing machine for automatically producing spring roll pastry, samosa pastry, egg roll pastry, and even crepe.

Spring Roll Pastry And Samosa Pastry Maker

SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is a food processing machine for automatically producing spring roll pastry, samosa pastry, egg roll pastry, and even crepe. Simply prepare batter and the SRP Series will automatically finish the rest of steps, including baking, cutting, counting, and stacking. Finally, the baked pastries are nicely stacked in piles, ready to be packed, frozen, and sold at any time. It is also a samosa pastry machine. Samosa pastries can be made with the same process except that the way of cutting is different. Cutter can be customized as required. Want to get a quick quote and consultant? Please click the button below and fill out the form.

Specifications

Power

45A (35 kW), 45B (38 kW)

Capacity (pastry of 200 x 200 mm)

2,700 pcs/hr, 9 m/min

Thickness of pastry sheet

0.4–0.8 mm

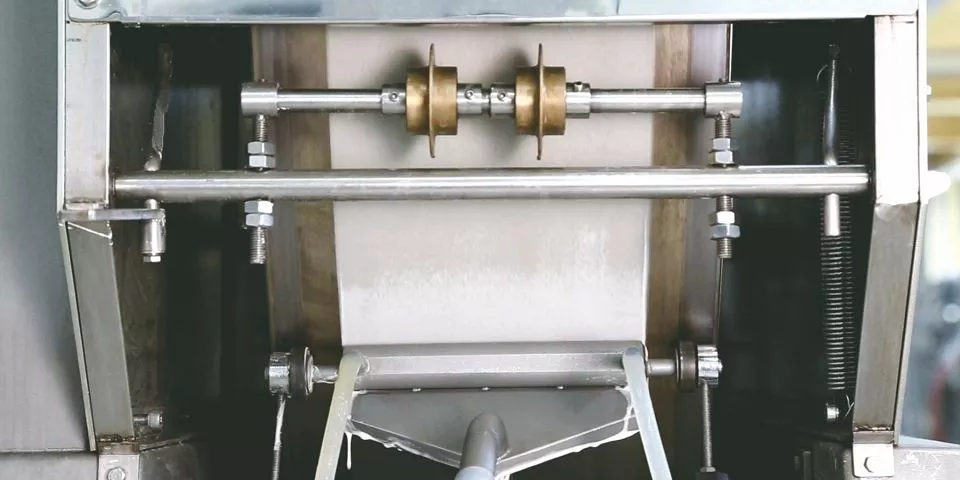

Including pastry baking drum, one nozzle, 2.5 m cooling conveyor, rotary cutter and counting device, and stacking conveyor.

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

How It Works

Previous

Next

Food's Gallery

Samosa Pastry

Samosa Pastry

Food Produced By This Machine

Blini

Nalesniki

Samosa Pastry

Spring Roll Pastry

Spring Roll

Palacsinta

Features

- Unique and Reliable Design:

Micro-computer temperature controller can maintain a set temperature within ±1°C. The baking drum is covered by a safety guard to keep from being injured by the heat. Simply feed the well-mixed batter into hopper, machine will spray and bake batter, then cool, cut, count and stack pastry sheets automatically. - Process of Pastry Sheet Production:

MIXING -> FEEDING -> BAKING -> CUTTING -> COUNTING -> STACKING - High capacity and uniform products