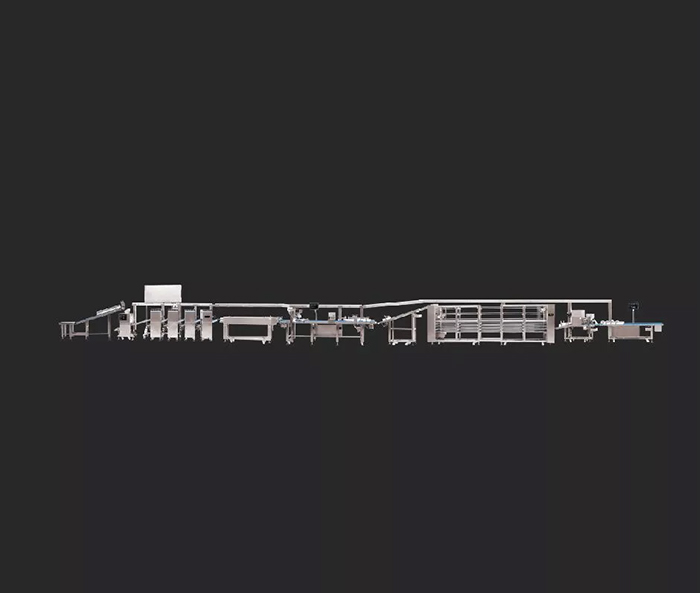

Model: LAP-5000

Lacha Paratha And Green Scallion Pie Production Line

The crispy layers of parathas or scallion pancakes are craved by people. ANKO's Lacha Paratha & Green Scallion Pie Production Line can produce parathas and scallion pancakes...

Lacha Paratha and Green Scallion Pie Production Line

The crispy layers of parathas or scallion pancakes are craved by people. ANKO's Lacha Paratha & Green Scallion Pie Production Line can produce parathas and scallion pancakes with extremely thin layers because it features a dough stretching device, which can stretch dough into a 0.8 mm thin sheet. By simply putting dough, scallions, and oil, the Lacha Paratha & Green Scallion Pie Production Line can mass-produce Chinese pancakes, scallion pancakes, and parathas automatically.

Specifications

Dimension

27,480 (L) x 1,420 (W) x 2,400 (H) mm

Power

0.4 kW

Capacity

2,100–6,300 pcs/hr

Product Weight

50–130 g/pc

Air consumption

1,200 L/min (@ 6.5 kg/cm^2)

Production capacity is for reference only. It'll change according to different product specifications and recipes. Specifications are subject to change without notice.

How It Works

Previous

Next

Food's Gallery

Flaky pancake

Multiple layered and flu...

Scallions evenly rolled ...

Rolled up dough balls

Dough balls are perfectl...

Perfectly pan-fried para...

Food Produced By This Machine

Scallion Pancake

Lacha Paratha

Paratha

Features

- More efficient dough feeder Incline conveyor with an automatic feeding control sensor makes the feeding process smoother.

- Maintain dough texture 4 sheeting rollers gradually roll a chunk of dough into a dough sheet to avoid too much pressure to destroy dough texture.

- Extremely thin layer The stretching device stretches the dough sheet into 0.8 mm.

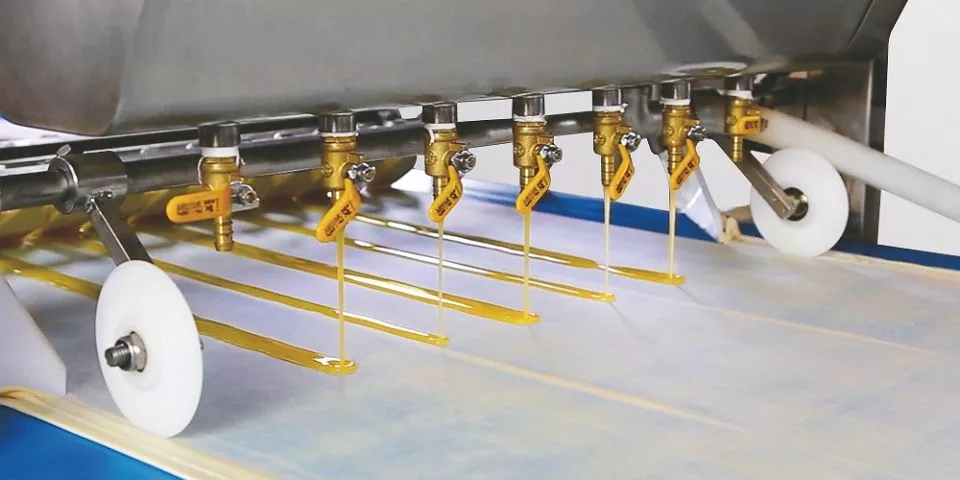

- Automatic oil feeder with temperature controller Makes the solid fats and liquid oil drip and keep the feeder unblocked.

- Scallions sprinkled evenly The automatic sprinkling device sprinkles chopped scallions evenly on the dough sheet.

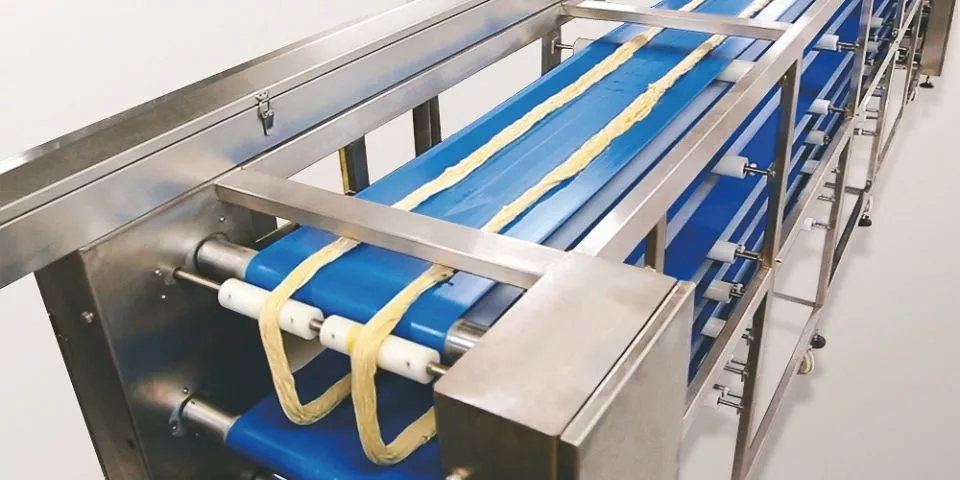

- Conveyor designed for dough resting The conveyor is 35 meters long to let the dough rest 8 to 10 minutes.

- Roll up dough strips for more layers According to the dough texture and product size, install the proper weight and number of the stainless steel wire mesh for perfectly rolling up the dough strips.

- Optional machinery Automatic Filming and Pressing Machine is available to bundle to continue pressing the roll-up dough balls and filming them for packing.

- One button to quickly start the entire production line

- Cable trunking helps keep cables tidy to make the factory safe and hygiene

- With only 3 persons for operation. One person feeds dough and ingredients and two persons collect products. Case Studies