Model: EMP-900

Automatic Food Filling & Forming Machine

ANKO’s EMP-900 Empanada Making Machine can process high fat content pastries such as pie dough and puff pastry; it can also process both cooked and raw ingredients that have different textures and consistencies. ANKO’s unique filling mechanism gently keeps ingredients such as corn kernels, peas, and diced potatoes intact assuring the final product’s appearance and texture resemble handmade Empanadas.

Specifications

Dimensions

2,740 (L) x 900 (W) x 2,140 (H) mm

Power

0.9 kW

Capacity

900 pcs/hr

Product name

Empanada, Curry Puff, Calzone

Product weight

30–130 g/pc

Filling hopper capacity

45 L

Air consumption

400 L/min (@ 6 kg/cm^2)

Weight (net)

415 kg

There are many product molds that can create flat pattern, traditional pattern, and fork pattern as well as double-sided print molds that are rarely available for automated forming machines. ANKO can also provide customized empanada molds upon request.

EMP-900 is compact in size (only 2.5 square meters/26.9 square feet) and has a maximum capacity of 900 pieces per hour using the Ejection Mold Device for demolding food product with high efficiency. This machine is suitable for automated food preparation production to supply food trucks, central kitchens, chain restaurants and small to medium sized food factories. If you are interested in more information about this ANKO machine, please click on the link below, and complete the form. ANKO’s professional consultants will get back to you as soon as possible.

How It Works

Previous

Next

Food's Gallery

Fork pattern

Flat pattern

Traditional pattern

Ladder pattern with doub...

Customized pattern

Seal-tight

Clear pattern after deep...

Empanada texture can be ...

Whole corn kernels

Food Produced By This Machine

Empanada

Curry Puff

Calzone

Chebureki

Panzerotti

Features

Examples are pie dough or puff pastry dough made with an oil water solution that contributes as much as 75% of the weight of the dry ingredients.

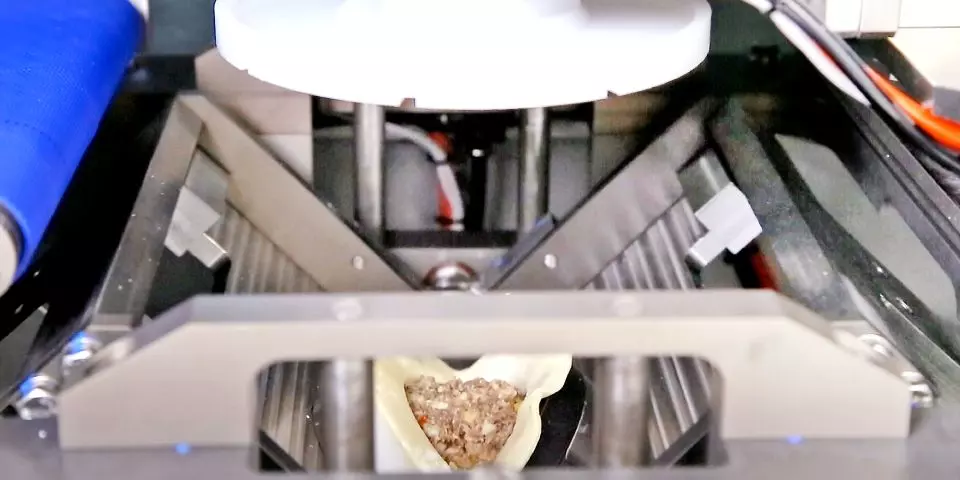

Prevents ingredients such as peas, corn kernels and other ingredients with a maximum radius of 10mm from being crushing during the filling process.

Capable of processing raw or cooked ingredients with different consistencies and moisture contents.

Replaces the manual demolding process and increases production efficiency.

Helps to increase product brand recognition, such as using company logos or using ANKO’s double sided print molds to create unique products.

Only two simple steps to switch from one production line to another.

The “Clamping Mold Device” consists of one part made with Polyoxymethylene (POM) a food grade engineering thermoplastic material, and the other part is coated with Teflon to ensure food safety.

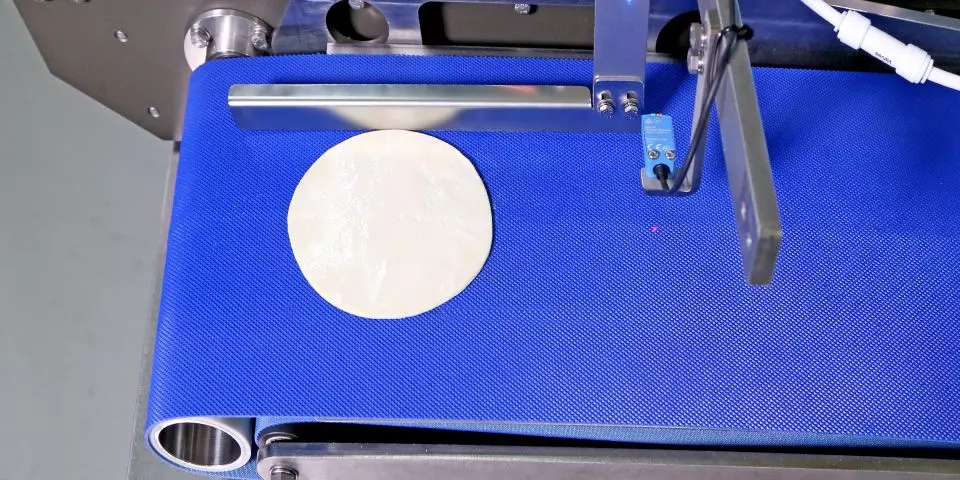

Infrared sensor detects the radius of the dough wrapper and places the filling in the center, thus ensuring product consistency.

This machine can be easily cleaned and sanitized to ensure food safety.

Optional Accessories

Rotary mold, Noodle mold, CE kit

Pattern

Flat Pattern

Traditional Pattern

Fork Pattern